Engineering works and integration

Our multidisciplinary engineering team at C-Job offers extensive expertise across all phases of the ship life cycle, ensuring we can respond swiftly and effectively to your engineering and integration needs. We work as an extension of your team, or directly with the shipyard, to make the transition from design to construction smoother.

What we deliver

We provide cost-effective and efficient engineering and integration services, backed by strong expertise in 3D modeling and detail design.

Flexible support

We take on the whole scope or just part of your project

Proactive and cost-effective

We meet your immediate engineering demands, rapidly and cost-effectively

Dedicated teams

Access our global team of engineers, IT consultants, supervisors and project managers

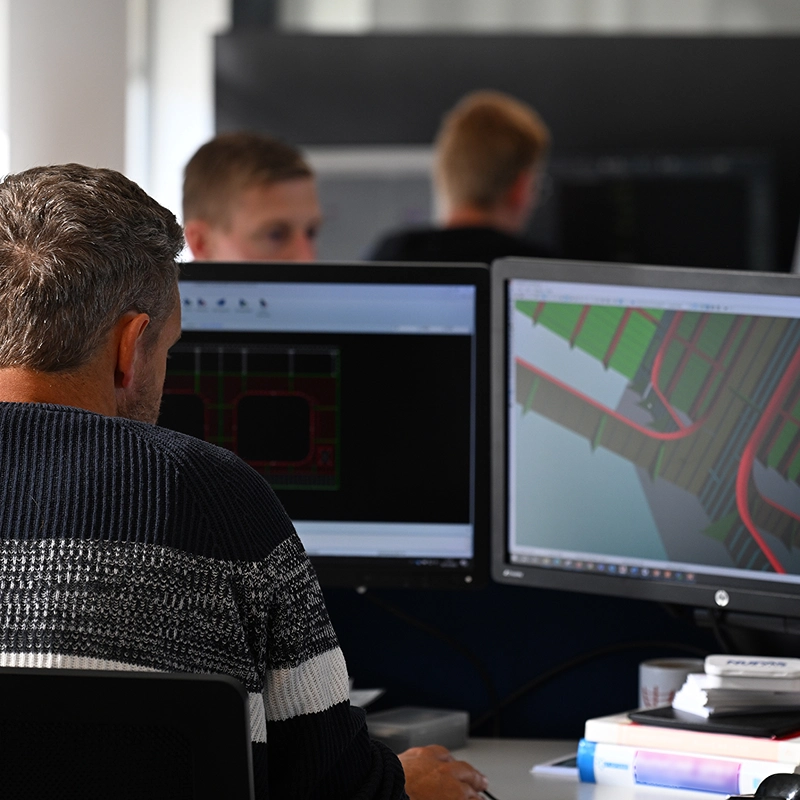

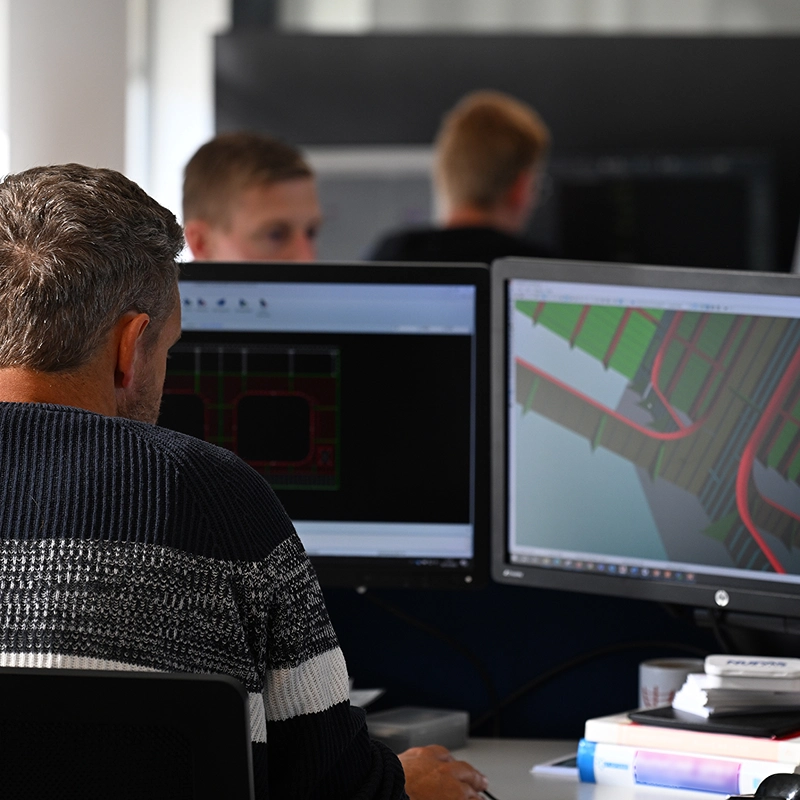

Advanced 3D engineering

Our experts use the latest high-end software to streamline design and engineering

Services we provide

Whether you require a simple update to your vessel’s plans or comprehensive engineering solutions, we’re here to help.

Hull design services

Our team can provide comprehensive support for naval architecture tasks such hull design, repair and maintenance, and outfitting solutions tailored to your needs – all according to current regulations and standards.

C-Job finite element analysis (FEA) engineers have extensive experience in structural and buckling analyses, and scantling calculations for ship hull structures. This includes the hull elements themselves, machinery integrations, complex equipment, plus global analysis and structural optimization of the hull. We provide basic design and 3D modeling which can then be further developed into detail design, production drawings and construction plans.

Outfitting and equipment arrangement

C-Job provides a full range of outfitting and equipment arrangement services. Our multi-disciplinary engineers create 3D modeling and production drawings that simplify the production process, with real-time updates on steel, pipes and equipment, weight estimations as well as material take-offs that can be used by the shipyard to place precise material pre-orders. We also design elements that enhance the functionality and reliability of the vessel, such as masts, anchor pockets, deck cranes and deck elements.

Conceptual and detailed machinery space arrangements

We develop conceptual designs and initial layout plans for machinery spaces, based on functional requirements, maintenance access, and operational needs. This ensures space optimization and compliance within design constraints, safety standards and for classification societies. Detailed design then refines these layouts with precise dimensions, and incorporation of all equipment and fittings.

Pipe and systems routing

C-Job has considerable expertise in designing piping systems for a variety of vessels, including tankers, container ships, mega yachts, dredgers, and offshore platforms. We use cutting-edge technologies and incorporate the most recent industry standards and codes into our design process to ensure accurate and effective piping arrangement drawings. We also provide design routing for HVAC systems, electrical cable trays and other equipment.

Machinery outfitting

C-Job engineers can assist with the selection, installation, and maintenance of your vessel’s machinery, ensuring optimal performance and efficiency. Our specialists help to calculate the capacity and type of equipment to maximize economy and efficiency. Our support ensures that machinery layouts optimize space, reduce vibrations and facilitate maintenance access, while adhering to classification society standards.

Component modeling

Component modelling ensures accurate placement of equipment in engine rooms and other technical spaces. It also enables optimum routing of pipes, and correct access to equipment and other components. The process is crucial to ensure an efficient installation process, lower production costs, and increase maintainability of equipment in the vessel. We have strong skills in creating detailed 3D models of your vessel’s components, to optimize the design process across all disciplines.

As-built documentation

Our team of skilled engineers will create or update accurate as-built documentation for your vessel, capturing all modifications, deviations, and adjustments made during the build process compared to the original design. This provides a valuable resource for future maintenance and repair work. The documentation package will include detailed piping design and specifications, and cataloguing of all equipment and components such as connections, service spaces, and footprints for foundations.

Deck equipment

C-Job helps you integrate and install deck equipment of any complexity – including cranes, winches and bollards – for any type of vessel. We perform equipment calculations in accordance with classification society requirements, and use advanced software to ensure integration is completed efficiently and quickly.

Grillage integration

Our naval architects and engineers have extensive experience in providing calculations, designs and integration for grillage systems, which provide a safe and stable base for heavy or oversized cargo. We provide advice on the right solutions for your vessel, taking into account cargo type, weight and ship stresses, and use advanced software to create the most effective and compliant solution.

Statutory documentation

We can prepare and update stability booklets and safety plans for your vessel, ensuring compliance with the latest regulations and best practices, including the requirements of classification societies. This includes calculations for a ship’s intact stability, damage stability and hydrostatics, plus inclining tests and reports.

Related case studies

Green Jade – for CSBC

Fishing vessels and workboats – for Padmos

Lorraine Hooks – for Mike Hooks LLC

Download the whitepaper

This whitepaper explores how a holistic approach to vessel design can enhance offshore wind operational efficiency. By integrating data-driven analysis, project-specific equipment, and optimized vessel sizing, companies can reduce risk, control costs, and improve vessel performance.