Modernization and conversion for existing vessels

C-Job modernization projects will extend a vessel’s life cycle, adapt its business use case, increase its capacity, or ensure compliance with the latest regulations including carbon and NOx emissions reduction.

Whatever the reason for modernization and conversion, we have a wealth of knowledge in repurposing vessels for new markets and missions. We fine tune your vessel to achieve the performance and compliance required by the business case, within budget and with minimal downtime.

What we deliver

We help you implement the best modernization and conversion approaches, using our years of experience and dedicated team of in-house designers and engineers.

Flexible support

C-Job can scale your team size up or down, to streamline modernization and conversion

Tailored, holistic approach

Our holistic approach will optimize and tailor your vessel in the most efficient way

Peace of mind

We balance cost with mission goals to limit surprises and ensure project success

Transparency

We give you greater visibility into project progress, improving collaboration and cost control

Services we provide

Whatever your challenge – from reclassification to incorporating future fuels – C-Job partners with you to deliver the capabilities your vessel needs.

Surveys and assessments

C-Job will perform comprehensive surveys and assessments to demonstrate that your vessel modernization or conversion will deliver business value and a return on investment. We determine feasibility, evaluate the impact of changes including equipment integration, and perform a clear risk assessment. This holistic view of your existing’s vessel performance, as well as objective and unbiased advice on its modernization or conversion, give you peace of mind moving forwards.

Energy efficiency

Vessels performance and operational costs can be improved considerably with energy-saving measures and best-fit technology solutions. Our team carefully analyzes the original design of your ship and its current usage to identify where discrepancies exist. By aligning the vessel’s design and usage, we can help you improve performance and energy efficiency through appropriate and practical modernization.

3D scanning

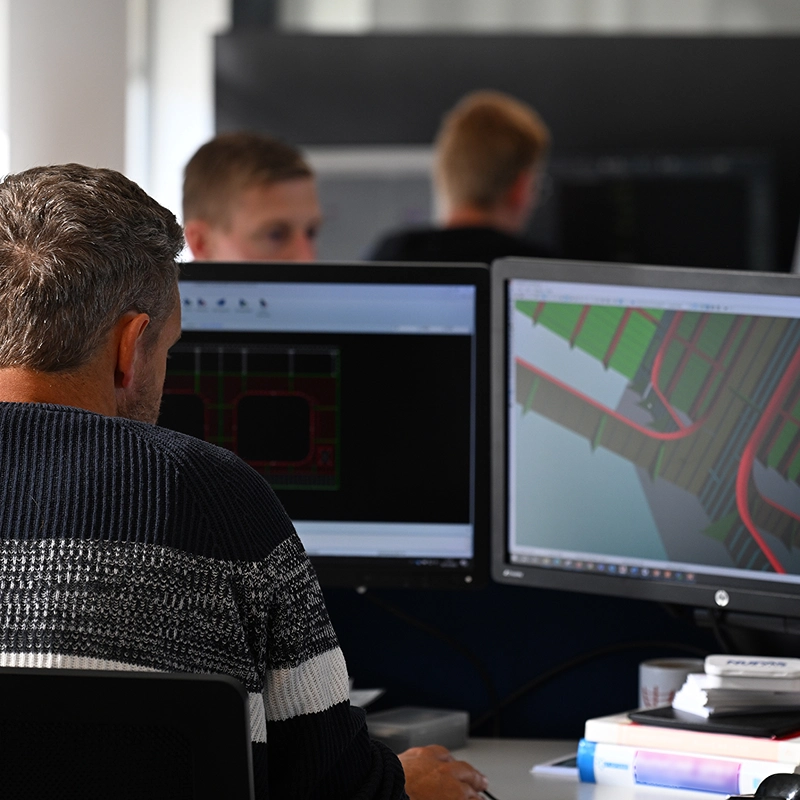

We are highly skilled in using laser scanning and drawings to generate 3D models in Cadmatic and other software. A scanned model rather than construction documentation is essential for retrofit projects, since over time differences can occur between the actual vessel’s frame spacing, equipment arrangement, or pipe routing and the ship’s original documentation. By accurately matching the design of the current vessel in 3D, we avoid collisions.

With C-Job, scans will be made by engineering experts who capture all elements with sufficient details, and the scans and reverse engineering work can be kept in the same team to improve efficiency.

Hybridization and repowering

Regulatory requirements and the need to achieve your ESG goals mean that the business case for modernizing vessels to alternative and future fuels is an increasingly compelling proposition. As a knowledge leader in the implementation of maritime decarbonization solutions, C-Job enables your shift to hybrid and more efficient power and propulsion systems to be performed cost-effectively.

Our multi-disciplinary teams will work with you to ensure the right technologies are chosen, to match the operational profile of your vessel now and into the future.

Design and engineering support

C-Job provides naval architectural and maritime engineering support for the entire modernization design process: concept, basic and detail design. Working closely with our designers and engineers, you will see your modernization come to life.

Yard support

We act as your eyes and ears at the shipyard, to ensure your vessel is built according to our joint plans. This can include reviewing project plans, drawings, evaluating vendors and, if required, managing stakeholders at the shipyard. A dedicated person or team at the shipyard has access to over 200 C-Job engineers to efficiently resolve issues, wherever that support is needed in the world.

Our onsite support services include weight surveys, construction support, inclining tests, and equipment integration and installation, to provide peace of mind that construction meets the highest standards.

Related case studies

Fishing vessels and workboats – for Padmos

NH₃ Kraken – for Amogy

Download the whitepaper

This whitepaper explores how a holistic approach to vessel design can enhance offshore wind operational efficiency. By integrating data-driven analysis, project-specific equipment, and optimized vessel sizing, companies can reduce risk, control costs, and improve vessel performance.