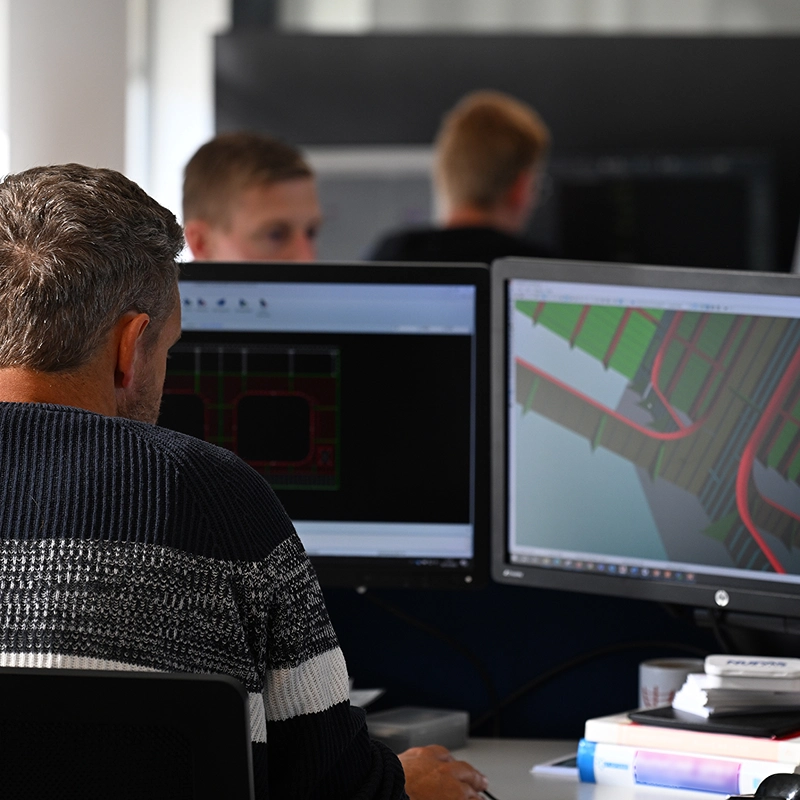

Design and engineering for new-build vessels

C-Job brings a passion for high-quality engineering and a deep understanding of business requirements to your vessel design, every step of the way.

We drive and control efficiency and performance in numerous ways, fully integrating design and engineering, and using the power of data science tools, AI, hull shape optimization, transparent project management – and much more – to ensure your new-build vessel will be high quality, future-ready and meet business and financial objectives.

What we deliver

Designing a new-build vessel is a complex and multifaceted process. Rather than making assumptions, we use real-life data to optimize the vessel design and ensure the best-fit with your operational goals.

Data-driven design

We focus on real-life data insights and the business case to optimize your vessel

Advanced levels of integration

Across the full life cycle of your vessel’s design, from concept to completion

Technology know-how

Unbiased, holistic advice on the latest technological advancements

Better design outcomes

We design and engineer more efficient, compliant, and sustainable ships

Services we provide

Our services cover the full spectrum of design and development, fully integrated to drive efficiency, and also offered individually.

Operational profile analysis

Our operational profile analysis uses proprietary methodologies and real-life data to simulate operational and economic scenarios. The analysis provides insights into fundamentals such as vessel size, optimizing fuel consumption or calculating the budget for mission equipment.

Assumptions made at the beginning of the design process are validated or refuted, to enable data-driven design choices to be made. This optimizes and tailors your vessel’s design to the needs of the business, enhances operational performance and ensures cost-efficiency from the outset.

Hull shape optimization

C-Job has implemented a new way of working in the vessel design phase. We use optimization, algorithms and automation to accelerate sections of the classic design spiral. The algorithms – developed in-house by C-Job – speed the hull design process and optimize hull resistance, which results in superior building costs (CAPEX) and operational costs (OPEX) for shipowners.

Holistic design and engineering

Our decades of design expertise allow us to create one-of-a-kind designs that are finely tuned to the customer’s needs. Your project will be driven by real data insights and C-Job’s extensive field experience, through all phases of vessel design to ensure stability and continuity. We offer the necessary resources you need in-house, and support you in coordinating external engineering resources.

This holistic approach to naval architecture, structural, mechanical, systems and electrical engineering, plus interior design and engineering, brings your vessel to life in a tailored way that delivers all the capabilities and performance required.

Yard support

We act as your eyes and ears at the shipyard, to ensure your vessel is built according to our joint plans. This can include reviewing project plans, drawings, evaluating vendors and, if required, managing stakeholders at the shipyard. A dedicated person or team at the shipyard has access to over 200 C-Job engineers to efficiently resolve issues, wherever that support is needed in the world.

Our onsite support services include weight surveys, construction support, inclining tests, and equipment integration and installation, to provide peace of mind that construction meets the highest standards.

Sea trials, compliance and certification

We see your projects to completion with rigorous sea trials and compliance verification. Our services include inclining tests, creating and updating stability booklets, and ensuring that all performance metrics meet the agreed specifications.

We also manage the certification process with your preferred classification society and the flag state to ensure your vessel complies with all relevant regulations.

Feasibility studies

C-Job’s expert engineers have completed numerous feasibility studies, and can perform detailed investigations into project scope and risk, market trends, defining the right technology, choosing future fuels, assessing environmental impact and technical feasibility, and much more. Our findings and advice help you make investment decisions with confidence, and support forward planning and construction.

Related case studies

Proof in the water

A new CSD 30″ – for the Port of Portland

New generation push boats – design for thyssenkrupp Veerhaven

Lorraine Hooks – for Mike Hooks LLC

Download the whitepaper

This whitepaper explores how a holistic approach to vessel design can enhance offshore wind operational efficiency. By integrating data-driven analysis, project-specific equipment, and optimized vessel sizing, companies can reduce risk, control costs, and improve vessel performance.