Researching the viability of ammonia as a marine fuel

With the International Maritime Organization seeking to reduce total annual GHG emissions by at least 50% by 2050, it is vital that the global maritime industry looks into renewable fuels like hydrogen, ammonia and methanol.

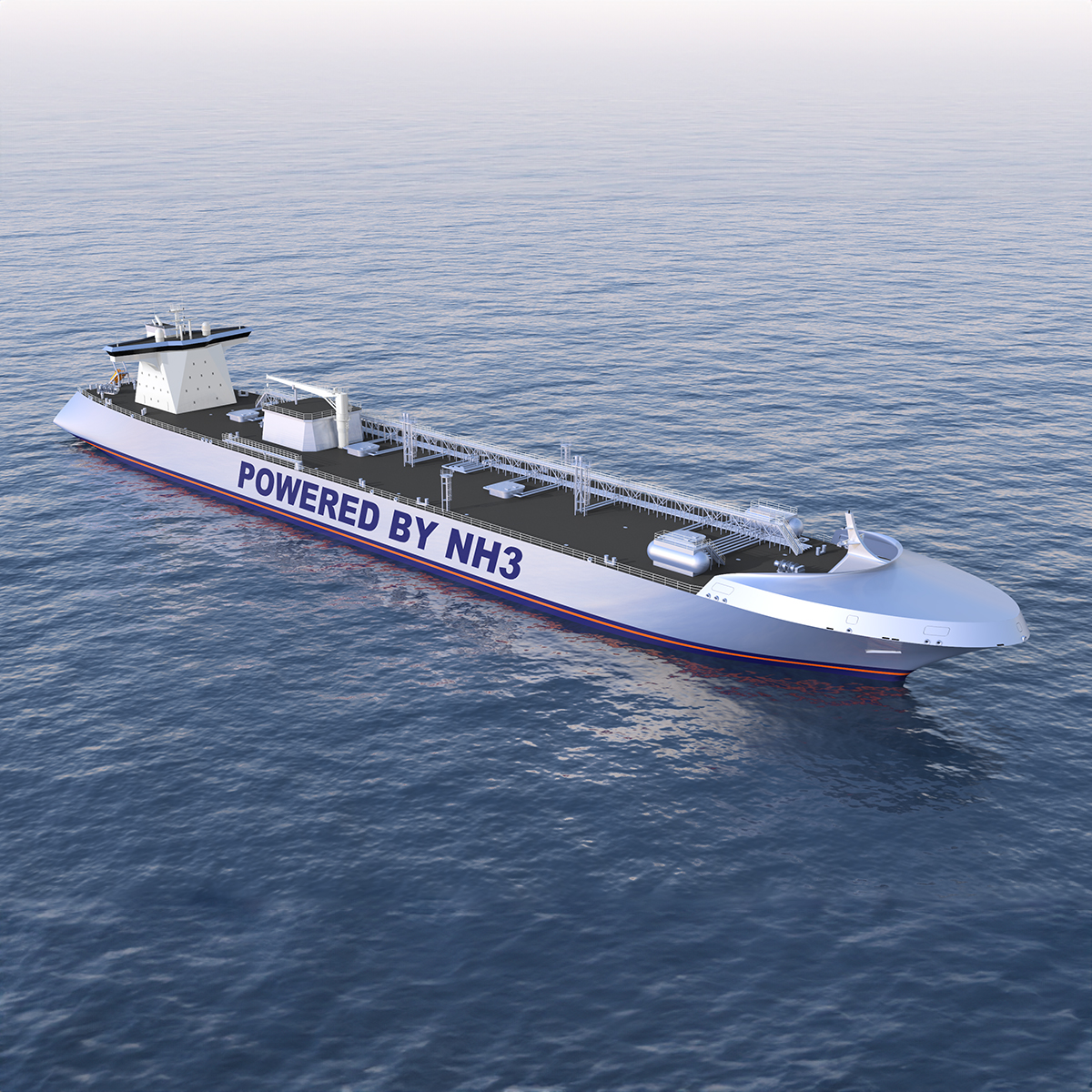

An ammonia carrier concept was used by C-Job to study the concept of using ammonia as a marine fuel. Due to an abundance of sources for hydrogen and nitrogen (which together make ammonia), ammonia could be produced in large quantities as a fully renewable fuel.

Our research, performed over three years, investigated different options for power generation using ammonia: a steam turbine, gas turbine, internal combustion engine (both compression and spark ignition) and fuel cells (both proton exchange membrane, alkaline and solid oxide fuel cells).

Due to the practical challenges of power density and load response capability, C-Job’s research demonstrated that an internal combustion engine using an ammonia diesel (ICE-CI) is the best initial solution, followed by an internal combustion engine using an ammonia hydrogen mixture (ICE-SI). In the long term, using a Solid Oxide Fuel Cell (SOFC) is potentially the most efficient solution.

An additional challenge to overcome is expanding the infrastructure of cargo ships so that more cargo space is dedicated to fuel. As expert naval architects, C-Job are ideally qualified to provide the most efficient ammonia vessel designs. These can reduce tank-to-propeller GHG emissions by more than 80% in dual-fuel marine engines.

The global shipping industry accounts for around 3% of global energy-related CO2 emissions, and C-Job’s research is an important step towards validating the vast potential ammonia holds for transforming the shipping industry.

Ammonia carrier

Project highlights

Risk-based approach

Analyzing the challenges of using ammonia as a fuel onboard a vessel

Award-winning research

Niels de Vries, C-Job’s Lead Naval Architect, wins Maritime Designer Award

Reduction of emissions

Identifies ammonia’s potential for reducing tank-to-propeller emissions

Ammonia carrier

C-Job specialist testimonial

Ammonia carrier

Scope of work

Design and engineering for new-build vessels

Decarbonization, energy efficiency and compliance

Ammonia carrier

Related case studies

Nuclear study for a bulk carrier

Chemgas Sno, Storm, Sumatra – for Chemgas