Hull shape optimization

C-Job's hull shape optimization tool uses one of the most advanced proprietary algorithms of its kind in the market.

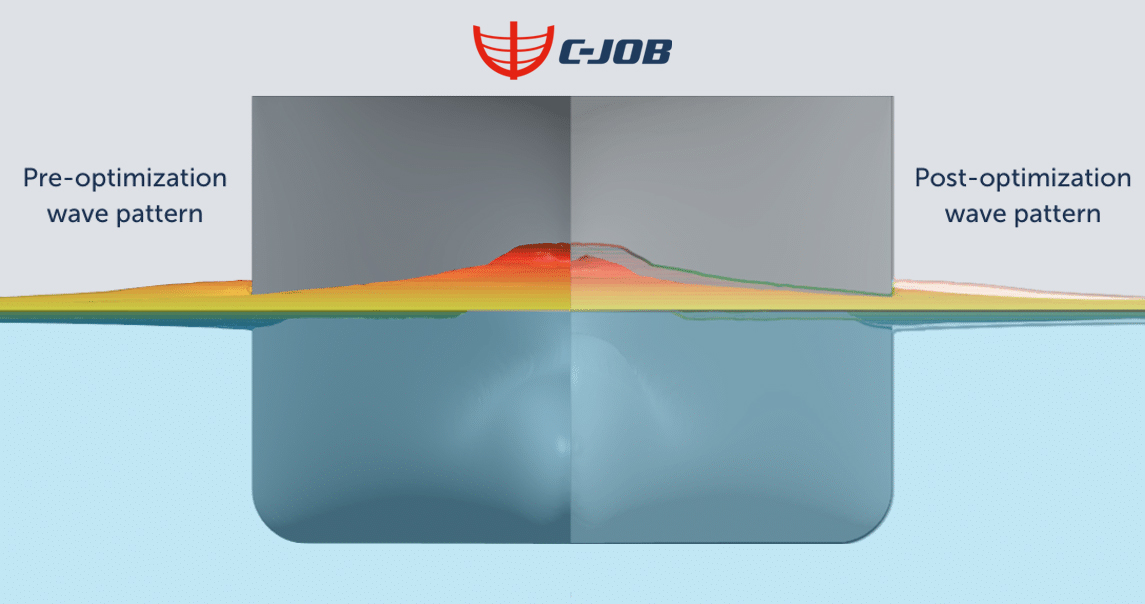

The optimization process learns from reliable resistance and hydrostatics data in combination with Computational Fluid Dynamics. New hull shape parameters are automatically modelled on a 3D platform before being analyzed afresh by the algorithm. Each iteration brings us closer to a final, optimized hull design, which our naval architects assess before producing a report of their findings.

By optimizing the hull shape, we directly influence factors such as the optimum speed for your vessel, fuel consumption or even ease of construction – which deliver costs savings and an optimized vessel long into the future.

Hull shape optimization

Discover more

Ahead of the Curve: C-Job Pioneers State-of-the-Art Optimization Tool

Any naval architect will tell you that computational fluid dynamics (CFD) software is the greatest thing since the towing tank. And rightly so. The simulation software eliminates the need for elaborate model tests and is conducive to a faster and smoother design process. Experts use it to model anything from underwater appendages to hull forms.

Fully electric ferry – for Saronic Ferries

Based on our history and experience in electric ferries, C-Job was engaged to work on a fully electric, zero-emission 85-meter ferry for Saronic Ferries in Greece. This concept design required C-Job to balance optimized onboard energy usage with sufficient battery power to meet the electrical propulsion demands of a longer-haul ferry.

Subscribe to our newsletter

Sign up for our bi-monthly newsletter, the NewsFlash, and keep up to date with C-Job news.