R&D: Dynamic Yacht Platform

Yachts are a masterpiece of engineering. Completely custom to each owner’s unique wishes. C-Job Naval Architects has developed faster engineering of high-quality custom yachts. The Dynamic Platform allows a yacht to be shaped by the owner’s vision and style, while reducing engineering time of technical and crew areas. This enables production of the yacht to start early, reducing time-to-market while ensuring high-levels of customization.

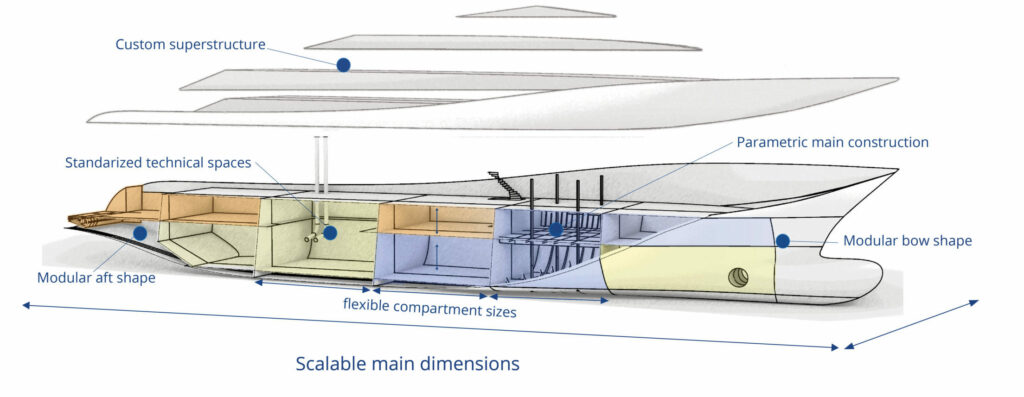

The Dynamic Platform is based on scale-to-order philosophy. It focuses on these ‘non-owner’ spaces – the technical and crew spaces in the lower part of yachts. Focusing on the commonalities found in the arrangement, construction principles and mechanical systems in the lower parts of custom yachts allows for smart optimization in a scalable platform. The technical solutions are standardized and scaled into a class- approved and flag state compliant model of the non-owner spaces.

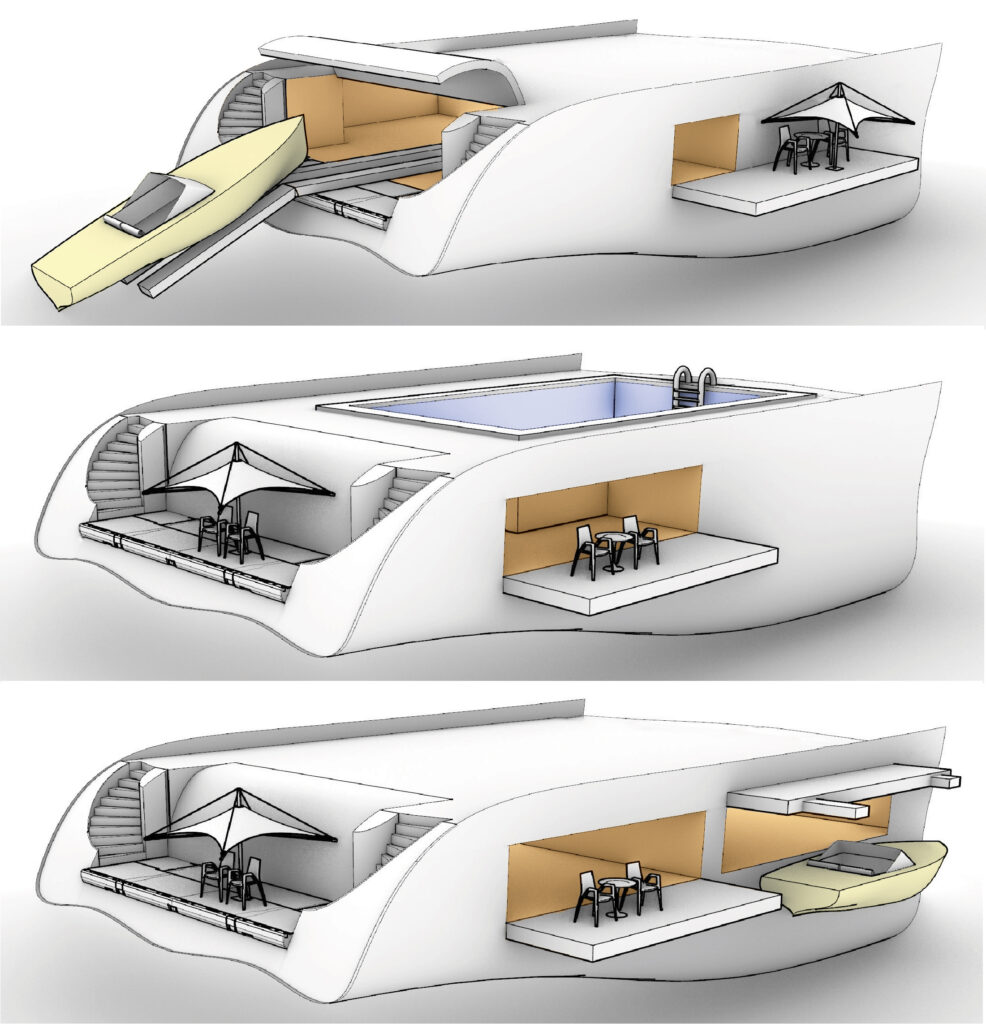

This disconnection of ‘owner’ and ‘non-owner’ spaces allows a yacht to remain highly customizable from the main deck upwards. The bespoke owner and guest spaces will continue to feature the owner’s wishes and vision with regards to functionalities, arrangement, exterior and interior while taking the vertical connections like staircases and funnels into consideration. Meanwhile, the lower deck is standardized to a certain degree yet tailor-made to their requirements.

Stefan continues “By eliminating the ‘space claim clashes’ and ‘grid mismatches’ via the Dynamic platform in an early stage of design, a significant design time reduction can be found of up to four-and-a-half months. This is half of the average time it currently takes to engineer the concept and basic design phase.

The Dynamic Platform focuses on the concept and basic design stages which results in reduced engineering time and early delivery of construction drawings required to start production. Time-to- market can therefore be reduced by at least three months in addition to reducing costs as engineering efficiency is increased.

“More research is needed to make the Dynamic Platform a reality, however, the first insights are promising. Not just for concept and basic design phases, detail engineering could benefit as well as yachts outside of the 50 to 80 meters ranges.”

Further development of the Dynamic Platform is in progress which may lead to further time-to-market reduction.

Principles and modularity

Based on the vision and requirements for the yacht design, a pre-defined global model with technical principles for the non-owner spaces is selected that is ready to be scaled. Each model is equipped with modular options that allow for customization of the non-owner spaces while the construction and mechanical principles remain intact.

Modular options include:

- Zone functionalities

- Hull shapes

Scale-to-order

Scaling of the basic design global model is based on geometry and the required capacities for each specific system and area. Up-scaling introduces more space in both the superstructure and the aft part of the platform. Downscaling equals cost reduction in materials and production.

Parametric scaling includes:

- Arrangements incl. WT/fire zones, escape routes

- Structural members

- Piping, ducting and cabling