Design modifications and integration of a powerful new crane

The Green Jade is a sister ship to the Orion, for which C-Job developed the concept design. However, with a different crane of 4,000 tons lifting capacity (versus the Orion’s 5,000 tons), C-Job naval architects and engineers had to adapt the design to meet different loads and ensure the vessel’s structural integration and stability. Compared to the Orion, the Green Jade was to be classed differently – ABS vs DNV – as well as having a double classification with Taiwan’s Classification Society (CR). This meant additional challenges had to be overcome, not only for the registration to the R.O.C. (Taiwan) flag, but also for operational considerations.

The project included integration of the Huisman-supplied main crane and its pedestal design, as well as the integration of propulsion thrusters and the auxiliary crane, which can be installed at multiple locations across the deck. The related intact and damage stability calculations were performed by C-Job using a NAPA model, and global FEA longitudinal strength checks were also performed.

Engineering works took place during Covid-19 which made the project far more of a challenge. The completed vessel carries an ENVIRO+ notation from the ABS.

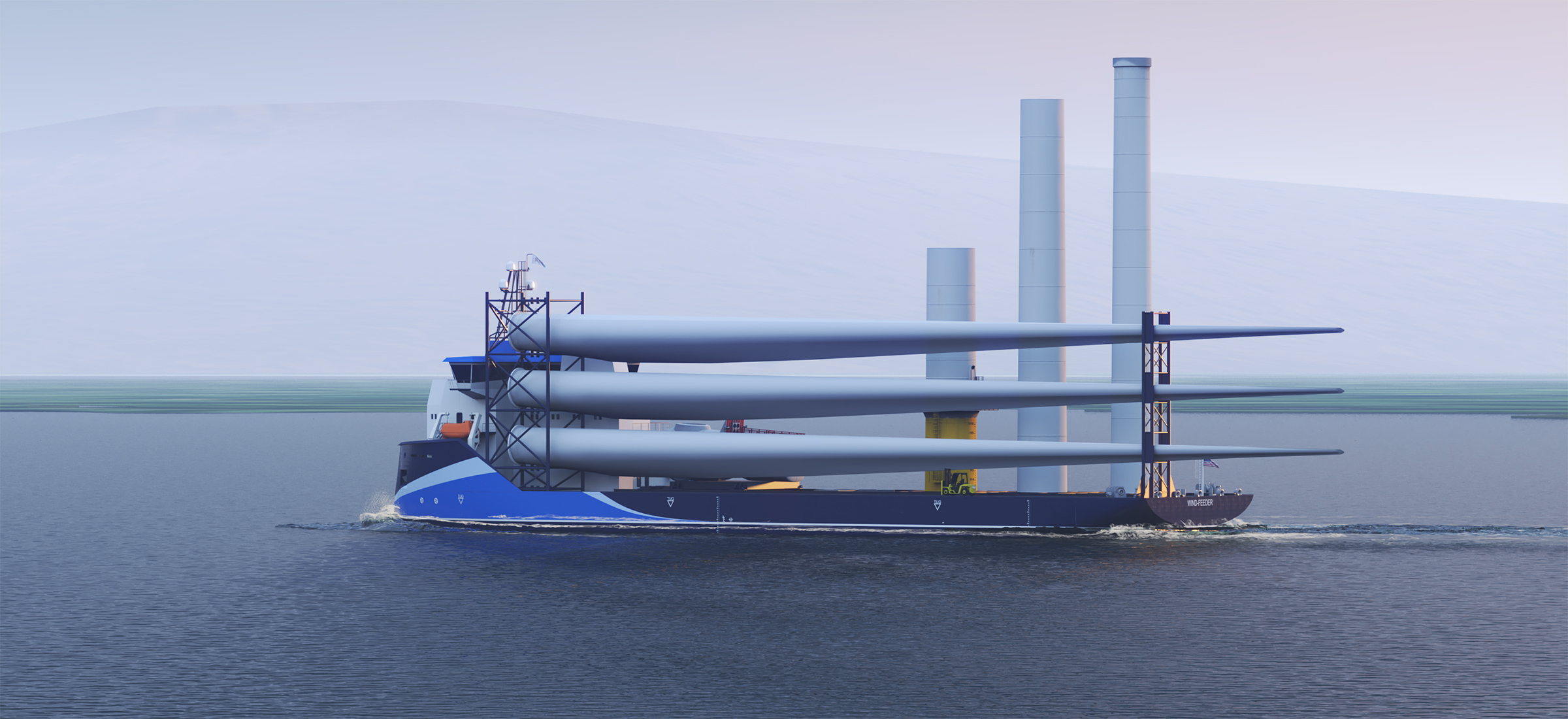

The Green Jade’s deck space is configured to transport an array of monopiles, jackets, wind turbine components and structures in a single shipment, thereby reducing both transport costs and reliance on support vessels. Since the Orion was designed for mainly installing monopiles, we supported CDWE with strength checks of the jacket transportations and pin piles on the Green Jade, and continue to support the company with the vessel’s actual mobilization on offshore wind farms.

The vessel has an overall length of 216.5 meters, a beam of 49 meters, a depth of 16.8 meters, a maximum draught of 11 meters, an 8,200-square-metre open cargo deck, deadweight tonnage capacity of 60,000 tons, and accommodation for up to 160 people.

Green Jade – for CSBC

Project highlights

Regional first

First Marine Installation Vessel (MIV) designed to support Taiwan’s energy transition

High specification design

Impressive loading capacity, lifting heights and advanced green technologies

Double classification

Double classed with American Bureau of Shipping (ABS) and CR Classification Society (CR)

Design upgrades and modification support

Adapted design for the main crane integration, including stability calculations

Green Jade – for CSBC

Scope of work

Modernization and conversion for existing vessels

Decarbonization, energy efficiency and compliance

Green Jade – for CSBC

C-Job Specialist testimonial

Green Jade – for CSBC

Related case studies