Initial design for a larger crane capacity

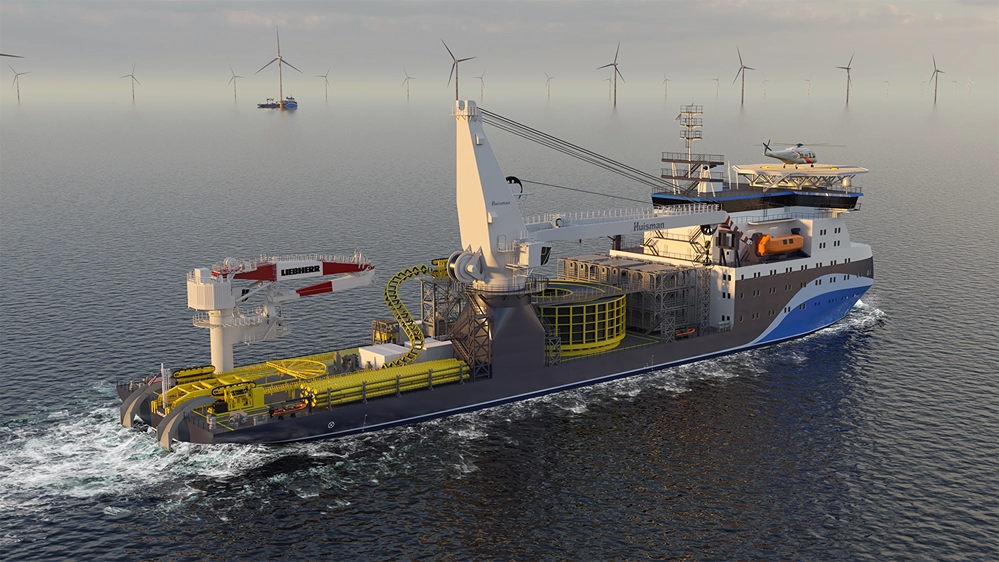

The construction support vessels in question perform subsea installation and small construction works in the North Sea, including lowering substations and hooking up seabed infrastructure.

We decided to perform an initial design using data analysis. Information on size and weight of future subsea installations translated into a requirement for deck area and crane capacity. A suitable equipment package specification from Huisman – a leading offshore crane manufacturer – was used for the project, which has an optional heavy compensation system design for working in high seas.

Offshore operations are all about safety and efficiency, therefore a well thought out and versatile deck layout was developed. The design has been assessed for potential future alternative uses of the vessel, such as cable laying or as an offshore service vessel with increased accommodation capacity and walk-to-work equipment.

C-Job performed feasibility checks and capacity stability calculations to ensure that the vessel could utilize the specified crane to its maximum capability in the harsh North Sea environment.

Special attention was paid to the vessel’s power plant. The power plant is designed to operate on both MDO and methanol fuel to provide both operational flexibility and long endurance, while also achieving reduced emissions when operating on methanol. The power demand of this vessel is typically highly fluctuating depending on the operation and environmental conditions. This power demand is typically challenging for dual fuel engines, therefore to achieve high fuel efficiency and low emissions during all operations, a battery system is included in the power plant design.

Our work is now a showcase design that will serve as a starting point for the full vessel design by the client.

Offshore construction vessel

Project highlights

Optimized deck layout

Initial design to ensure feasibility and maximum operational capability

Flexible and fuel efficient power plant

Dual-fuel and battery hybrid power plant for high efficiency

Powerful crane

400 mt crane capacity with lowering capability up to 3,000m below sea level

Offshore construction vessel

C-Job specialist testimonial

Offshore construction vessel

Scope of work

Design and engineering for new-build vessels

Decarbonization, energy efficiency and compliance

Offshore construction vessel

Related case studies

Green Jade – for CSBC