Improved efficiency versus barge feeder solutions

The current barge feeder approach to offshore installations relies on a number of tugs and support vessels. These can have a limited operational window due to ever-increasing transit times between the port and offshore site, and adverse weather conditions or high seas.

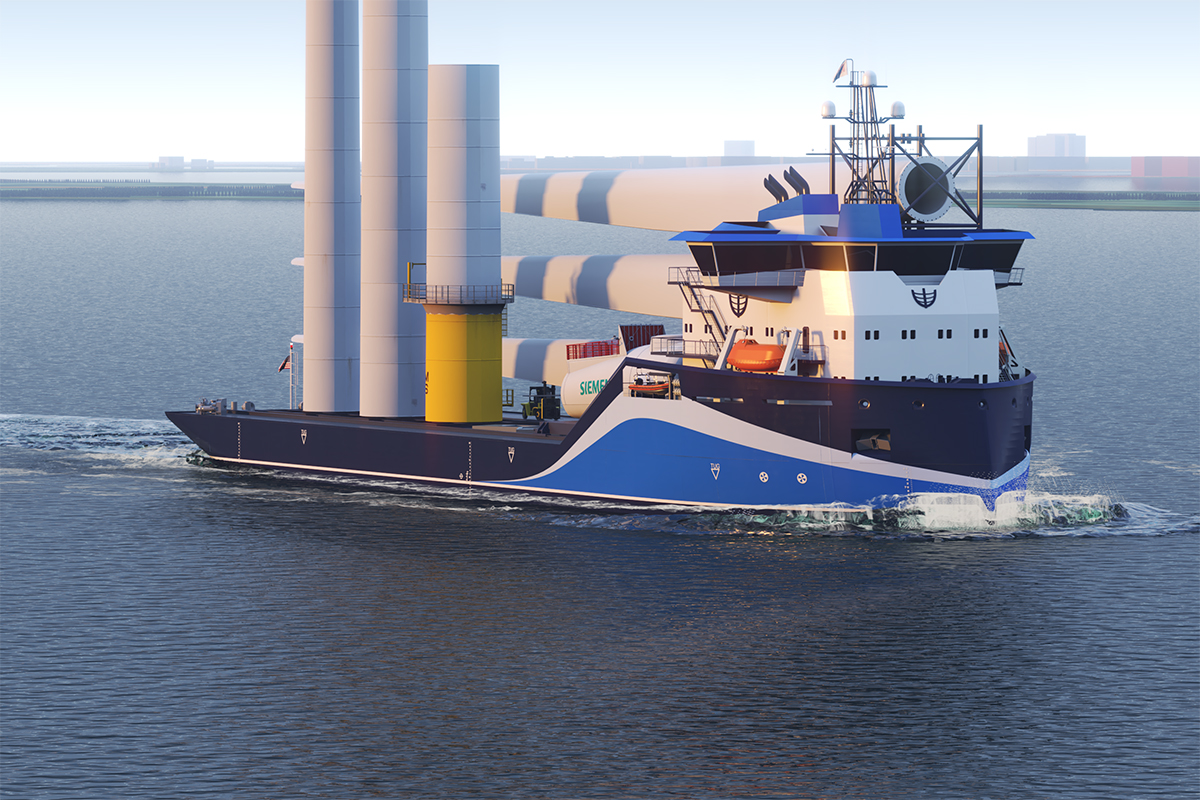

C-Job therefore saw the opportunity to meet the logistical needs of offshore wind farms. Our feeder vessel enables the transport of all wind turbine components, including blades, and can remain in the field as long as possible to improve efficiency. The ship is intentionally not designed to install turbines, which keeps the vessel relatively compact to minimize construction and operational costs.

C-Job worked with a specialist in motion compensation technology, Ampelmann, to enable the vertical transport of turbine towers and the offshore lifting of heavy components from the stabilized platform. This allows the crane operator to continue lifting in sea states of up to 2.5 meters significant wave height, which maintains installation efficiency.

Our design was developed specifically for the American offshore industry, which has ambitious plans to grow its installed offshore wind power capability. When not required for offshore wind projects, our vessel can also operate as a Service Operation Vessel, Platform Supply Vessel or Construction Support Vessel. The concept is envisioned to be a series of new vessels, specifically designed to meet the construction philosophy and needs of American shipyards.

Offshore wind feeder

Project highlights

Innovative design

Enables transport of vertical turbine components and blades

Increased workability

Motion compensation technology aids landing and lift-off of components

Purpose-designed

Created for the US offshore industry, and for efficient construction at USA shipyards

Cost efficient

Relatively compact length of 103.5 meters reduces construction and operational costs

Offshore wind feeder

Scope of work

Design and engineering for new-build vessels

Engineering works and integrations

Offshore wind feeder

Related case studies

Green Jade – for CSBC