Case studies

Explore a world of different C-Job projects for all vessel types, with a full range of C-Job services from design and engineering for new build vessels, modernizations and conversions, to future fuels and technologies that contribute to reducing harmful emissions.

NH₃ Kraken – for Amogy

C-Job is helping to pave the way for a greener shipping industry as a knowledge partner for Amogy,a dedicated specialist in ammonia-based energy solutions. We helped integrate the company's revolutionary ammonia-to-power system into the tugboat NH₃ Kraken, and supported onsite execution activities at the shipyard, including modernization, construction, engine removal, and other challenges.

Read more

Green Jade – for CSBC

C-Job supported CSBC with basic design and main crane integration for the Green Jade, the first heavy lift and offshore wind installation vessel built in Taiwan. The vessel, which features a crane with 4,000 tons of lifting capacity and DP3 capability, was launched by CDWE, a joint venture between CSBC and DEME Offshore, and entered service in 2023.

Read more

C-Job and LH2 Europe – liquid hydrogen tanker

C-Job has worked in partnership with LH2 Europe to develop an initial design for a liquid hydrogen tanker of 141 meters with a storage capacity of 37,500 cubic meters. The tanker concept is a critical element in realizing a green end-to-end liquid hydrogen supply chain.

Read more

A new CSD 30″ – for the Port of Portland

To maintain its shipping channel, the maintenance dredger Oregon has been hard at work for the Port of Portland since its construction in 1965. Due to its age, the Port reached out to C-Job to create a concept design for a new CSD 30”, to replace the Oregon, which could run on marine diesel oil and also be methanol-ready.

Read more

Offshore construction vessel

C-Job continuously evaluates the maritime sector and its evolving requirements. Based on signals from the marketplace, we saw the potential need for multiple construction support vessels, where crane capacity is lacking and existing ships are aging.

Read more

New generation push boats – design for thyssenkrupp Veerhaven

thyssenkrupp Veerhaven is exploring opportunities for a new generation of climate-friendly pusher boats: an EU Stage V emission standards push boat, and/or a dual-fuel methanol-diesel push boat. C-Job provided two different concept designs for each type of vessel, which had to navigate the river Rhine, deliver low OPEX, and provide good crew comfort.

Read more

Nuclear-powered commercial vessel

Research by C-Job demonstrates the potential for nuclear energy to become an alternative energy source which could contribute to the decarbonization of commercial shipping. This is in part due to the development of small modular reactors (SMRs) and advances in nuclear technologies. Additional C-Job studies explore new economical design speeds when using nuclear energy as a propulsion source for future cases.

Read more

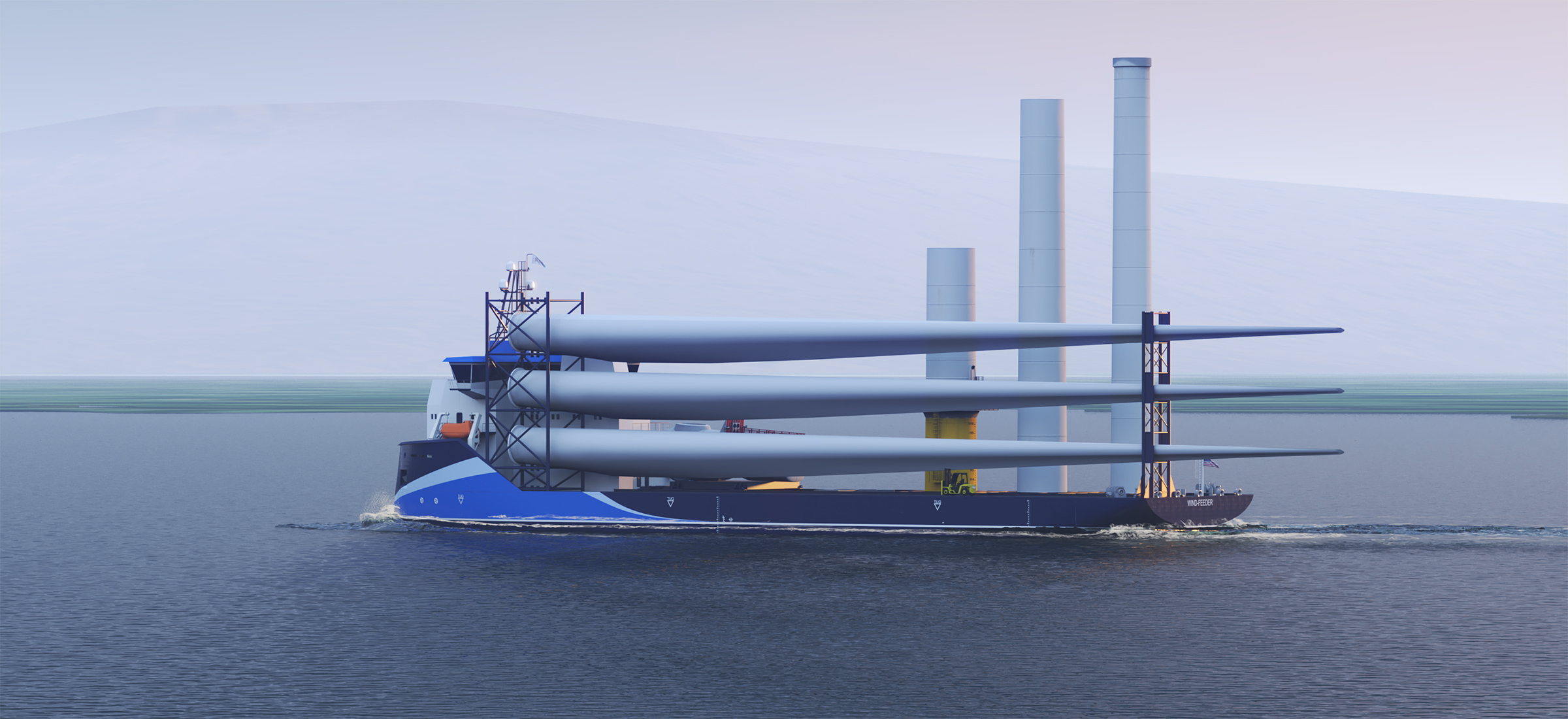

Offshore wind feeder

C-Job Naval Architects has created an offshore wind feeder vessel for efficient transportation of wind turbine components, initially for the US market. By acting as a feeder vessel, our concept increases the efficiency of local wind turbine installation vessels (WTIVs).

Read more

E-Pusher 1 – for Kotug

C-Job worked with Padmos, a family run shipbuilder, on behalf of their client and shipowner, Kotug. In 2021, Kotug launched its E-Pusher concept of fully electric pusher boat and barges, which are a world first. The concepts were created by Kotug, and C-Job collaborated with Padmos on the basic and detailed engineering for the first of these vessels, the E-Pusher 1.

Read moreSubscribe to our newsletter

Sign up for our bi-monthly newsletter, the NewsFlash, and keep up to date with C-Job news.