C-Job Discipline: Mechanical Engineering

To say that mechanical engineering is a broad subject would be a major understatement. It is a discipline that offers its skills to a huge area of ship design elements. From general arrangements and digital 3D models to the configuration of ship systems and components – the work of C-Job’s mechanical engineers can be found throughout a vessel.

For new build projects, their mechanical engineering input is used in all stages of the design process: from the very first Concept designs, all the way to Detail Design and construction drawings. Mechanical engineers also contribute to C-Job’s Building Supervision contracts or even lifting and rigging calculations, as well as the installation of mission equipment.

New builds and retrofits

“For new build designs, our department is responsible for turning our beautiful naval architectural drawings into fully operational vessels. Well thought out designs that are optimized to their situation. This encompasses propulsion, power, ship systems and internal climate,” says Misja Janzen, Mechanical Discipline Coordinator at C-Job, in what is actually a deceptively short summary of what mechanical engineering is. “We start off with the basics. What are the client’s needs? What is the main functionality of the equipment? For example, you may have the most beautiful wooden inlay in your yacht, but if the temperature and humidity are wrong, you will not feel comfortable. Or if your engine room is not properly designed, there won’t be any room for maintenance.”

The subject of mechanical engineering is not only important in designing new vessels: it plays an invaluable role in retrofit projects too. A timely example of this type of project is the installation of exhaust gas after treatment systems – otherwise known as scrubbers – that enable compliance with new emissions regulations.

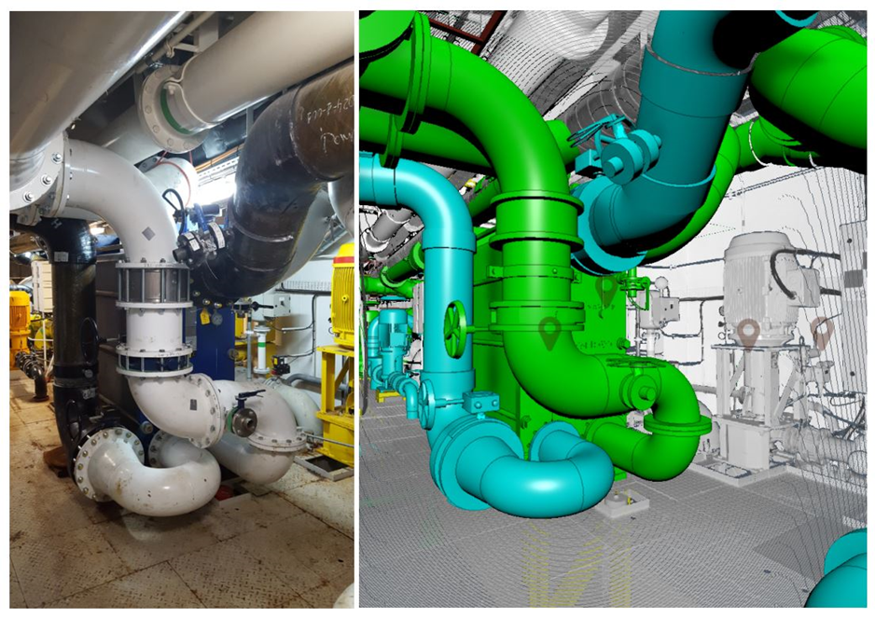

Obviously, the mechanical engineering challenges of retrofitting are very different from the ones posed by new vessel designs, as Misja explains. “If you look at a vessel that is 30 years old, it’s amazing to see how much the original vessel has changed over the years. This may include the addition of equipment and structural modifications. Therefore, the installation of even more equipment – scrubbers or ballast water treatment systems, for example, can be quite complicated. Making a 3D point clouds scan of the existing situation is the best way to start.”

Piping plans

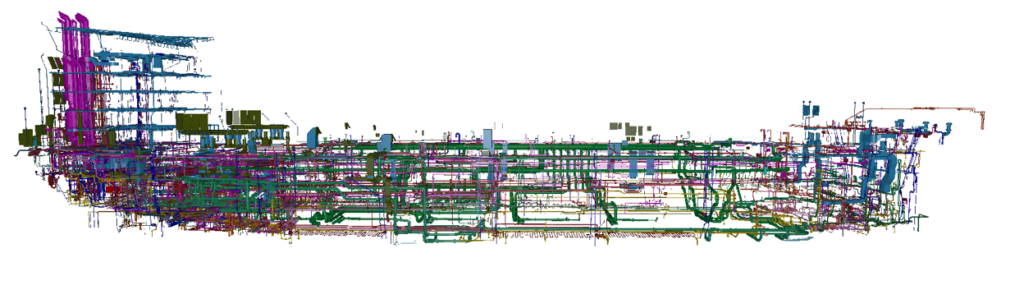

In achieving the all-important vessel functionality, a lot of C-Job’s mechanical engineering team is involved with piping arrangements. The image below illustrates the significance of piping. “This picture shows that, even with the structural steel of the vessel removed, you can still see the shape of the vessel. It is quite fascinating.”

As well as showing the importance of mechanical engineering, this image is also a great way to highlight how C-Job’s different discipline departments have to work together. “Every decision that we make is a decision that affects another discipline,” he notes. “If we decide to add more equipment, the vessel can become too heavy or unstable. If we want to cut a hole in a bulkhead, the strength integrity might be lost. If we want to make an air duct bigger, the interior department might not meet their requirements.”

The essence of C-Job

“Therefore, we have to come up with solutions that benefit the whole project, and not just our own department,” Misja states.

This statement is actually a very good way to describe the way of how C-Job operates. The company’s project management processes are finely tuned to enable effective internal communication and cooperation. “C-Job is growing fast, but we put a lot of effort in maintaining the ‘small company feeling’. This allows us to have proper communication between all departments – this is what makes us so strong. Even though we now have three offices in the Netherlands, one in Houston, and one in Ukraine, it still feels like a small company here.”