C-Job R&D: FPSO Optimization Tool

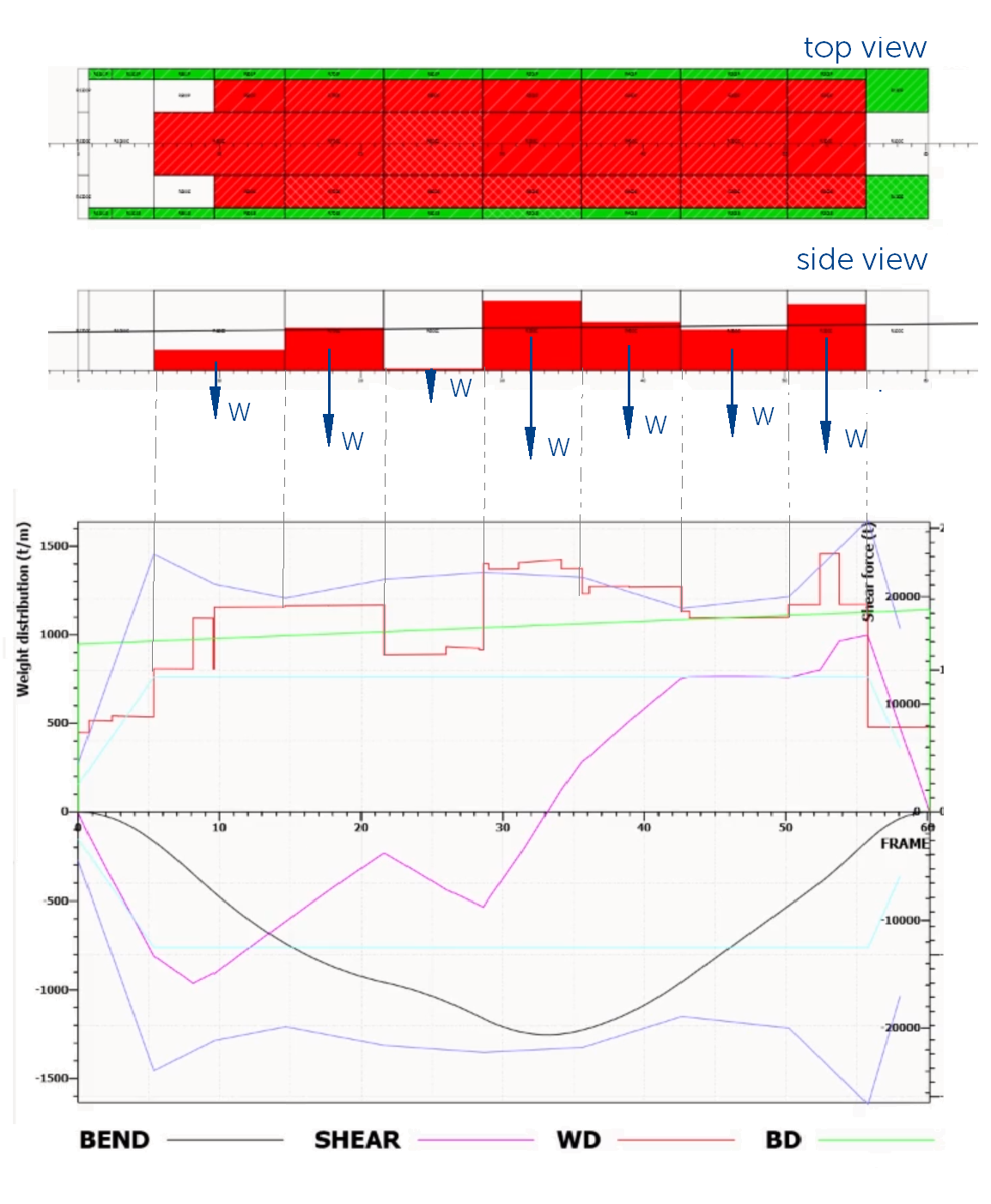

Maximizing the oil-carrying capacity of the vessel. That is by far the most important demand of operators of floating production storage and offloading units (FPSO) and other oil-carrying vessels. C-Job’s FPSO Optimization Tool is web-based application that allows operators to achieve precisely this. It analyzes a large number of different load combinations (each with its own unique balance of strength and stability) to determine the optimum loading configuration of a vessel. Put it another way: to carry the maximum amount of oil possible.

When would a tool like this be necessary? Jelle van de Ridder, R&D Engineer at C‑Job gives us the answer. “An operator can use the FPSO Optimization Tool when something in the weight distribution of the vessel changes. For an existing vessel, this can be when there are changes to the topside. For a new-build vessel, this is during construction

Volume + Arrangement + Weight Distribution

Although C-Job has developed the FPSO Optimization Tool clearly for the FPSO market, Jelle is quick to point out that it is applicable on all oil-carrying vessels. “This tool is not dependent on the capacity of the vessel; there are no boundaries regarding capacity. We can use it on the biggest FPSO or the smallest feeder ship.”

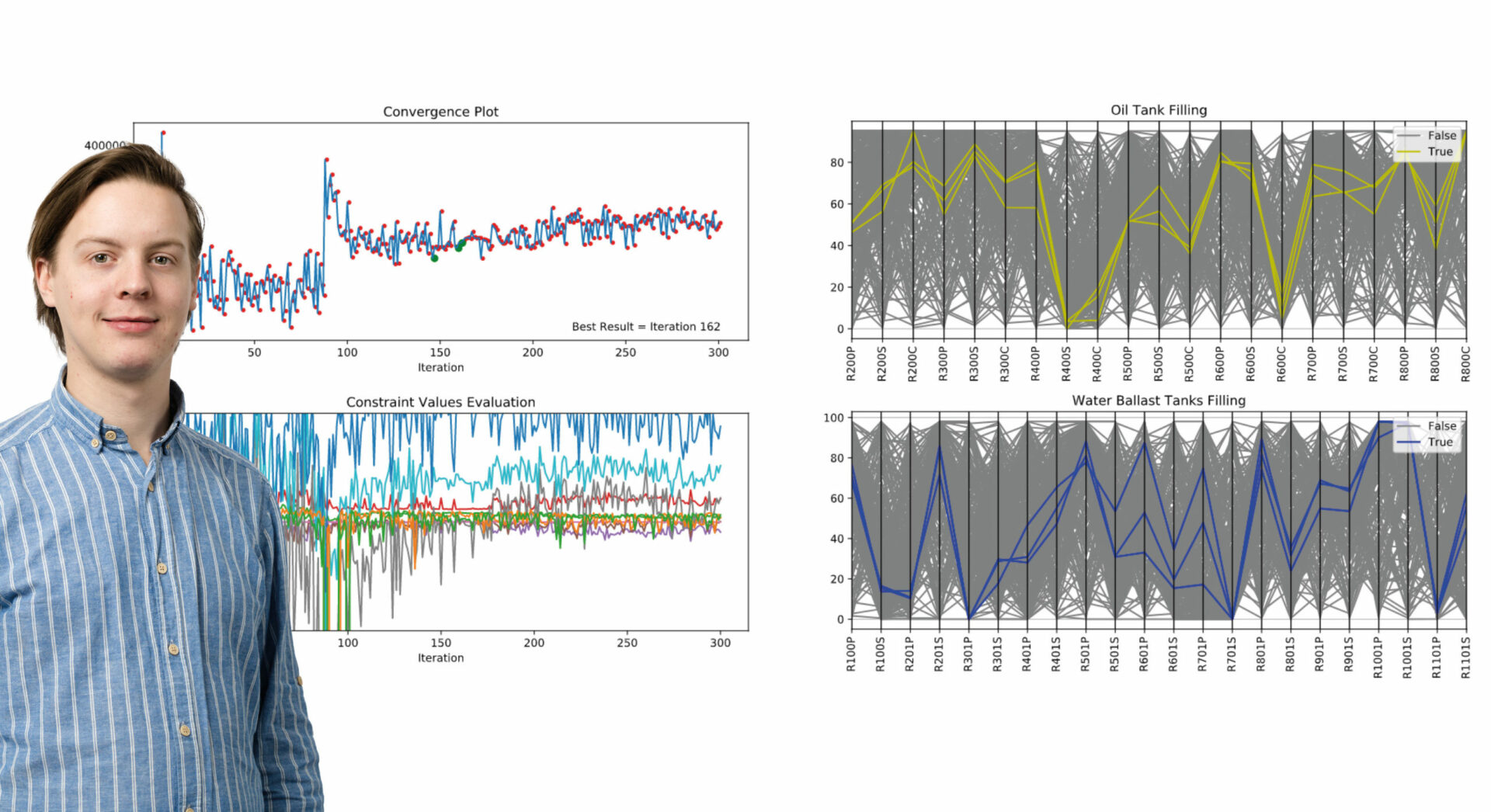

Jelle demonstrates the workings of the FPSO Optimization Tool by using an example of an existing vessel first. “Imagine the operator wants to increase the loading capacity. The first thing we have to do is model the vessel and identify the three key parameters of the volume of the hull that is under the waterline, the tank arrangement, and the weight distribution of the vessel. In general, this does not take too much time – especially if the client already has a 3D model.”

Calling on VIKTOR

In the case of a new-build vessel, the FPSO Optimization Tool will enable faster design phases. “Imagine you are designing an FPSO and you have three months to do the job. You will start off by performing repetitive load and stability calculations. Our tool will automate and speed up that process. It performs 300 iterations per hour, not only speeding up the process, but going above and beyond what a human engineer would be able to calculate throughout the entire design process. This gives you more time to focus on the non-repetitive design tasks, which improves either quality or lead-time. And, although less interesting for our clients, it is an added bonus is that it’s more fun for the engineer.”

C-Job produced the FPSO Optimization Tool with support from software developers from VIKTOR. VIKTOR Software Engineer Kevin van Giessen: “VIKTOR provides a low-code platform that gives our clients the possibility to build web-based applications using Python. As an open-source user-friendly programming language, Python, in combination with the VIKTOR platform is perfect for facilitating the building process because it uses pre-written building blocks.”

User-friendly interface

Kevin supported the creative process with C-Job over the space of four days. “One day of training followed by three days of software development. C-Job is very knowledgeable – we helped them integrate that knowledge into this web application – productizing their knowledge. C-Job’s R&D department is growing – tools like this will help them a lot. It can be used for internal use within the company, but also for clients and their vessels.”

This was the first time that C-Job has worked with VIKTOR, and Jelle is enthusiastic about the results. “What is so nice about VIKTOR is that they deliver a very clear user-friendly interface. It is very easy to understand.”

Trending topics

This article illustrates how data science and automation are contributing more and more to the design process. Notably, C-Job is in touch with this current trend in the world of naval architecture. Jelle sees the benefits; the FPSO Optimization Tool is an effective way to save C-Job’s naval architects time. “Automating these processes doesn’t remove the naval architect. It allows the naval architects to concentrate on the creative part of their job.”