Streamlining the Design Process: C-Job Nikolayev’s Expertise Using CADMATIC

The path from an initial design concept to a fully commissioned and delivered ship is long. In fact, the longer it is, the more expensive the ship will be for its owner. The more efficient and streamlined a naval architectural company can make that path the better. This is precisely what C-Job Nikolayev is achieving with improved design procedures paired with a comprehensive toolset.

The key to optimizing design methodology, says C-Job Nikolayev’s Director Andrey Zherebetsky, is to invest more time at the early stages of the design process – in particular during Basic and Functional Designs. “Unfortunately, it has become a trend in our industry to shift all the integration challenges of major components to the Detail Design and production stages,” he says. “While this is very convenient for design companies, it results in massive additional costs in the production phase at the shipyard.”

Optimizing procedures

After analyzing this particular problem, C-Job Nikolayev has taken an innovative approach to turn the tide of this rather inefficient trend. This draws on solutions designed by C-Job Naval Architects and further developed by the team at C-Job Nikolayev using CADMATIC 3D modeling processes.

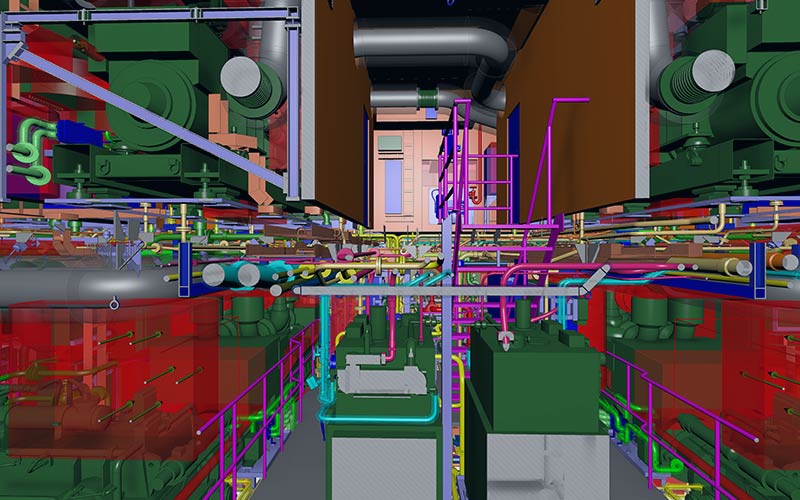

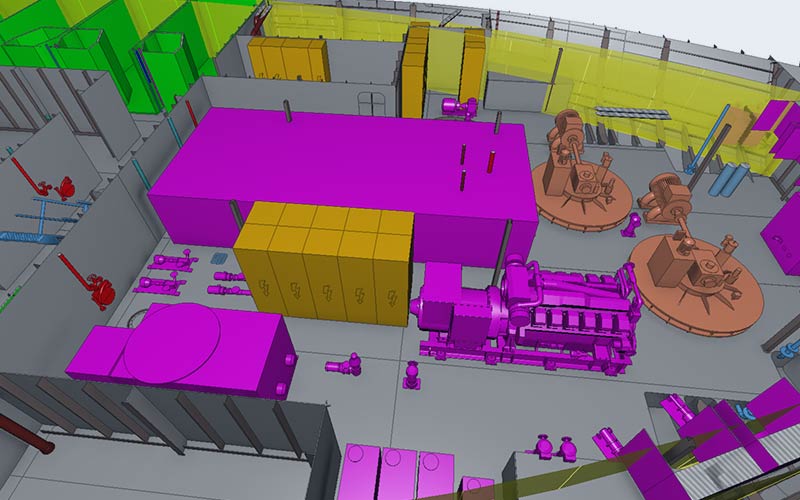

The result is that one of the biggest challenges faced by naval architects – the integration of all disciplines within Basic Design – is tackled head-on. It is fast and easy to create a CADMATIC model from the 3D initial/concept model and to create arrangement, structural and layout drawings,” explains Andrey. “Due to the unique and optimized procedures, we can respond quickly to changes and modifications with the CADMATIC Hull and Outfitting modules. Combined with the drafting functionality, we develop basic designs, taking care of the details and further production activities.”

With CADMATIC as an integral part of the company’s toolset, this methodology has become the standard way of working at C-Job Nikolayev. This has enabled C-Job Nikolayev’s engineers to provide fast and reliable design solutions for numerous maritime sectors.

Taking control

The ability to generate 3D Basic Designs is an important advantage of C-Job Nikolayev’s prowess with the CADMATIC software. “2D plans may be good, but 3D models take the design to the next level,” he goes on to say. “If you use only a 2D approach, some issues may only become evident during Detail Design, or even worse, during production. This has a big impact on resources, materials and planning. With a 3D model, we take control from the very start of the design process, already incorporating major equipment such as HVAC, cable trays, exhaust, engine room and machinery space arrangements.”

Furthermore, the CAMATIC software allows all participating parties to work in the same design environment. “Different teams and subcontractors may be working on different areas they’re responsible for, but thanks to the software they always work with the most up-to-date model.”

Point cloud designs

For both retrofit projects and newbuild designs for diverse clients, C-Job Nikolayev is carrying out an ever-increasing number of engineering projects with laser-scanned data. The company has successfully delivered more than 20 of these so-called ‘point cloud designs’ from 2018 to 2019. Once again, C-Job Nikolayev’s experience working with CADMATIC plays a crucial role.

“Working with laser-scanned data is fast, easy and efficient. The opportunity to examine an existing ship model with a laser scanner is advantageous compared to traditional ways of handling such projects. Point cloud implementation ensures project accuracy based on an existing ship model and that there are no unfortunate surprises during installation.”

Andrey Zherebetsky, Director C-Job Nikolayev