EEXI Compliance: using CFD can make the difference in your vessel’s ability to remain competitive

From 1 January 2023, EEXI Regulation comes into force. It is the first practical step in mapping emission output and vessels’ efficiencies in the maritime industry by the IMO. The result of many EEXI calculations is non-compliance.

The first solution considered is for shipowners to derate engines to comply, with some reporting having to derate engines down to 45% of their vessel’s installed power. This causes a substantial reduction of real operational speed and therefore decreases a vessel’s operational flexibility. But foremost, for vessels under charter contacts, it could mean they are no longer complying with contracts. For some shipowners, CFD reference speed investigation may present the solution for their ship to remain competitive demonstrating the real EEXI index.

First, a quick recap. What is EEXI? EEXI stands for Energy Efficiency Existing Ship Index. This regulation is a one-time document showing a vessel operates within the set emission limits by the IMO. All cargo and passenger vessels with a GT of 400 and above must be able to produce this documentation from 1 January 2023 onwards and to demonstrate the implementation of countermeasures (if required) at the first annual survey (emissions survey).

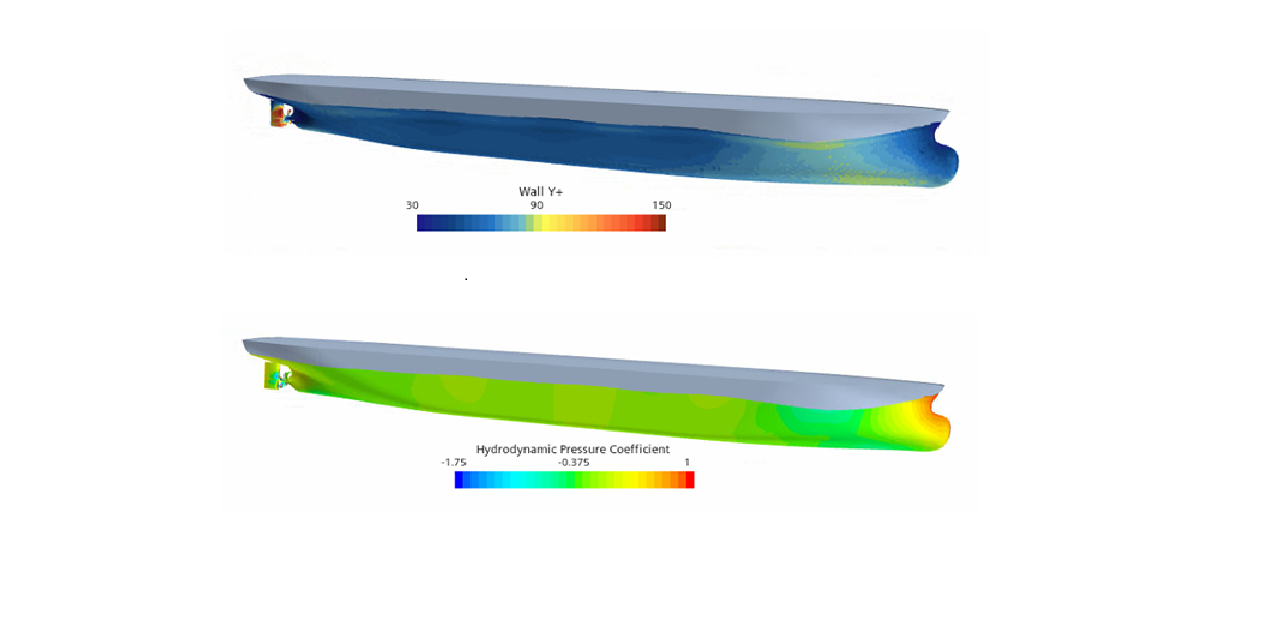

To create an EEXI technical file, various basic vessel parameters are used to calculate the performance at a certain loading condition. One of the parameters is the reference speed of VRef. Vref is the maximum speed that the vessel reaches under specific conditions taking into account DWT, engine load, draught, and more.

There are four ways to prove a vessel’s Vref. You can use either one of the following methods:

- Formula suggested by IMO

- Model tests

- Sea trials

- Computational Fluid Dynamics

Where both model tests and sea trials can be expensive ways to establish the VRef to prove EEXI compliance if no documentation is available. This will be often the case with second-hand vessels and sister vessels. This leaves the formula provided by IMO and Computational Fluid Dynamics options.

Filippo Iliopulos, Lead Naval Architect and Project Manager at C-Job, says: “We’ve found that the formula provided by IMO can be quite conservative in some cases. Using CFD rather than the formula can provide a more accurate Vref and sometimes be the difference between a vessel being able to remain competitive in the market or not.”

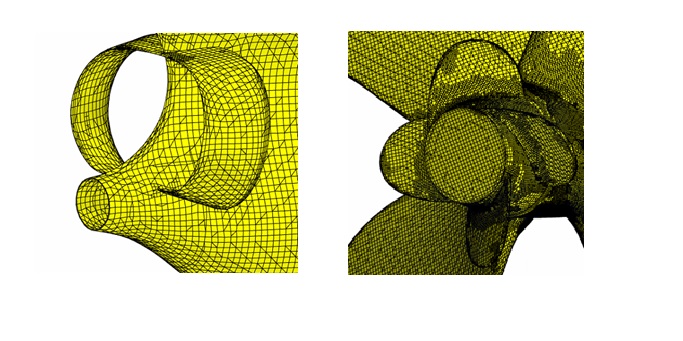

Schneekluth Duct mesh and Propeller Boss Cap Fins Mesh

CFD calculations are particularly useful for shipowners who have installed energy-saving measures on their vessels. This can be Mewis or Schneekluth ducts, Propeller boss cap fins, twisted rudders etc. for example. The data available in this case will be related to the old situation thus painting the wrong picture for EEXI documentation. CFD can prove the new situation of the vessel thus showing the real and higher vessel’s propulsive efficiency which could lead to compliance with the requirements even without the derating of the main engines.

Shipowners who own a series of similar vessels can also benefit from CFD. Where one vessel may not have the required data but a ‘sister vessel’ does, CFD can fill the gap regarding the lack of documentation.

If you’re looking for support on how to reduce the impact of keeping your vessel compliant with EEXI or have a query about your fleet, don’t hesitate to get in touch with us at sales@c-job.com.